The Importance of Project Management in Scientific Research n the realm of scientific research, project…

From Idea to Innovation: A Six-Step Process to Product Development

Developing a product is a dynamic and nuanced process, encompassing planned activities that enable a conceptualized idea to transform into a tangible, market-ready product. This blog post introduces each step of this process, where we’ll go from the inception of ideas to the mass manufacturing, ensuring a commitment to excellence and precision in delivering products customized to specific needs.

Phase 0: Proposal

In the initial phase, new ideas are assessed for feasibility. Product Briefs are developed and converted into practical project plans, outlining key deliverables and laying the foundation for the development process. During this phase, stakeholders converge to infuse these plans with collective wisdom, ensuring that the instrument resonates with the pulse of the market and the possibilities of cutting-edge technology.

Phase 1: Concepts & Specification

In this stage of product development, precision is key. Detailed planning occurs with the definition of User and Functional Requirements (URS & FRS). Ideas become tangible concepts carefully chosen to match the overall vision. Additionally, low-level design will help to fine-tune functionality and risk registration anticipates challenges. The highlight is creating proof-of-concept prototypes, giving life to the envisioned instrument, and bringing it closer to reality.

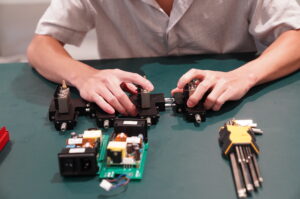

Phase 2: Alpha Prototype

Expanding on the groundwork, this phase emphasizes detailed-level design, prototyping, and thorough testing. Design Failure Mode and Effects Analysis (DFMEA) is handled, changes are documented, and technical reviews guarantee the improvement of the instrument’s design and functionality.

Phase 3: Beta Prototype

Continuing from Phase 2, Beta validation testing is conducted, addressing redesigns, and ensuring the instrument meets performance standards. Initial Confidence Testing, Performance Testing, and Secondary Functionality Testing guide the fine-tuning process, while DFMEA and change management persist.

Phase 4: Pilot Manufacturing

Moving from ideas to reality starts with making a small number of units. Detailed manufacturing procedure documents are established, certification applications are submitted, and Factory Acceptance Testing (FAT) is conducted to verify alignment with stringent quality standards. This practical step lays the foundation for the next stages, making the move from development to production smooth.

Phase 5: Data Pack & Release

With the instrument taking shape, the data pack is finalized, and a business plan should be developed. This phase sets the stage for the big launch, marking the initiation of mass manufacturing. It involves careful planning to position the product well in the market.

Phase 6: Mass Manufacturing

The main focus of this last phase is on delivering substantial quantities of tangible products, crafted with precision to meet specific needs. This phase shows a practical approach to efficiently fulfill requirements and guarantee a smooth supply of high-quality products.

Conclusion:

This comprehensive six-step process provides a structured approach to scientific instrument development, ensuring each phase contributes to the evolution of an idea into a market-ready product.

At Blacksheep, we thrive on complex challenges and applying creative engineering and analytical research to bring concepts to life. If you have an idea but are unsure of how to execute it, email us today at contact@blacksheeppower.com and our experts will get back to you as soon as possible. Elevate your projects with us – because at Blacksheep, innovation knows no bounds!