Redesign the Microfluidic pressure pump for optimal performance and cost-effectiveness

Background

Our client is a provider of microfluidics-based solutions, and they currently have an existing microfluidic pressure pump in their product lineup. The pump is well-regarded for its high precision and ability to deliver highly stable pulseless liquid flow. It has been widely recognized as one of the best available pumps for droplet formation in various microfluidics applications. However, the client seeks to take their product to the next level by developing a specialized high precision pump derived from their existing one.

Requirements

Addressing current issues

The new version aims to rectify the prevailing problems in the current pump design, notably the valve and orifice blockages. Additionally, the focus is on simplifying fabrication, assembly, and maintenance processes.

Cost reduction

An essential goal is to reduce production costs without compromising quality. This involves optimizing manufacturing procedures and selecting cost-effective materials to make the pump accessible to a broader range of customers.

Electronics upgrade

Given the potential obsolescence of existing electronics, a complete overhaul of the electronics system is required to ensure seamless compatibility and longevity.

Visionary changes

A comprehensive shift involves minimizing the use of cables and tubes within the pump while transitioning to coda pins for connections. Externally, the removal of gas supply tubes, wire cables, and signal wires between pumps is envisaged.

Slimmer design

The new cover must be moldable without requiring painting and should be thinner than the previous version.

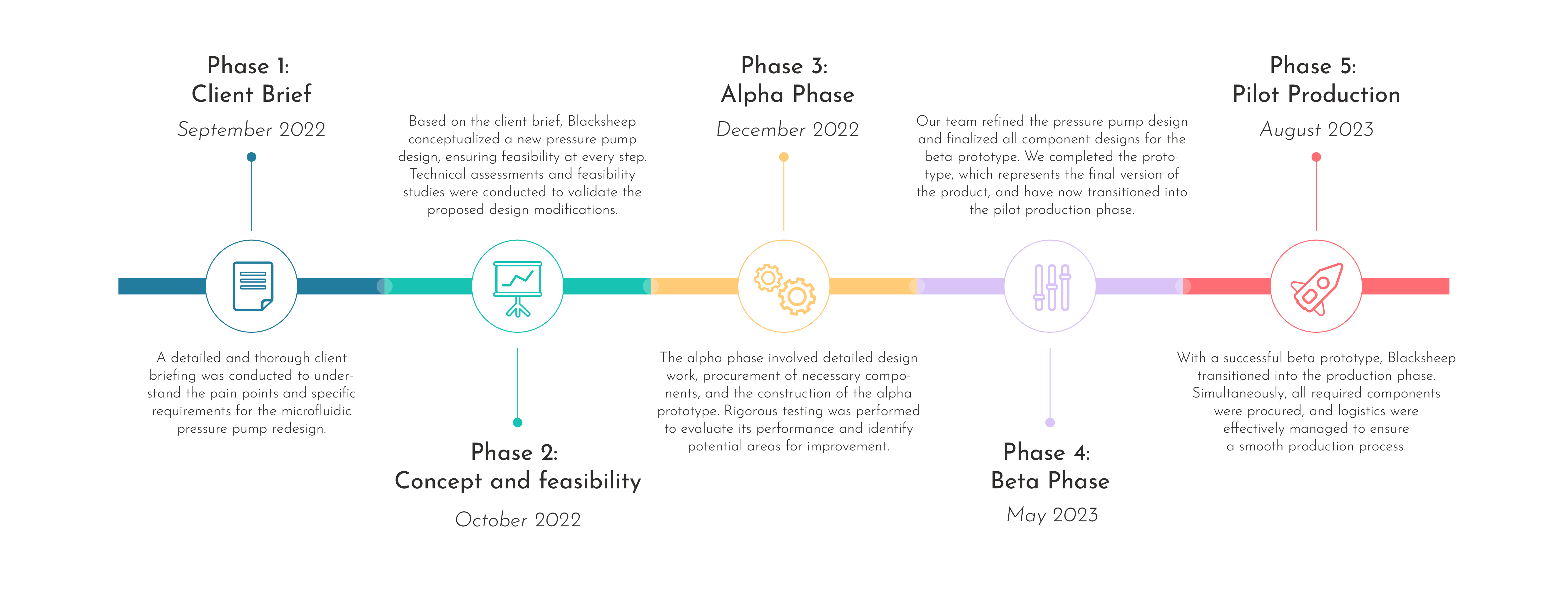

Design and Development Process

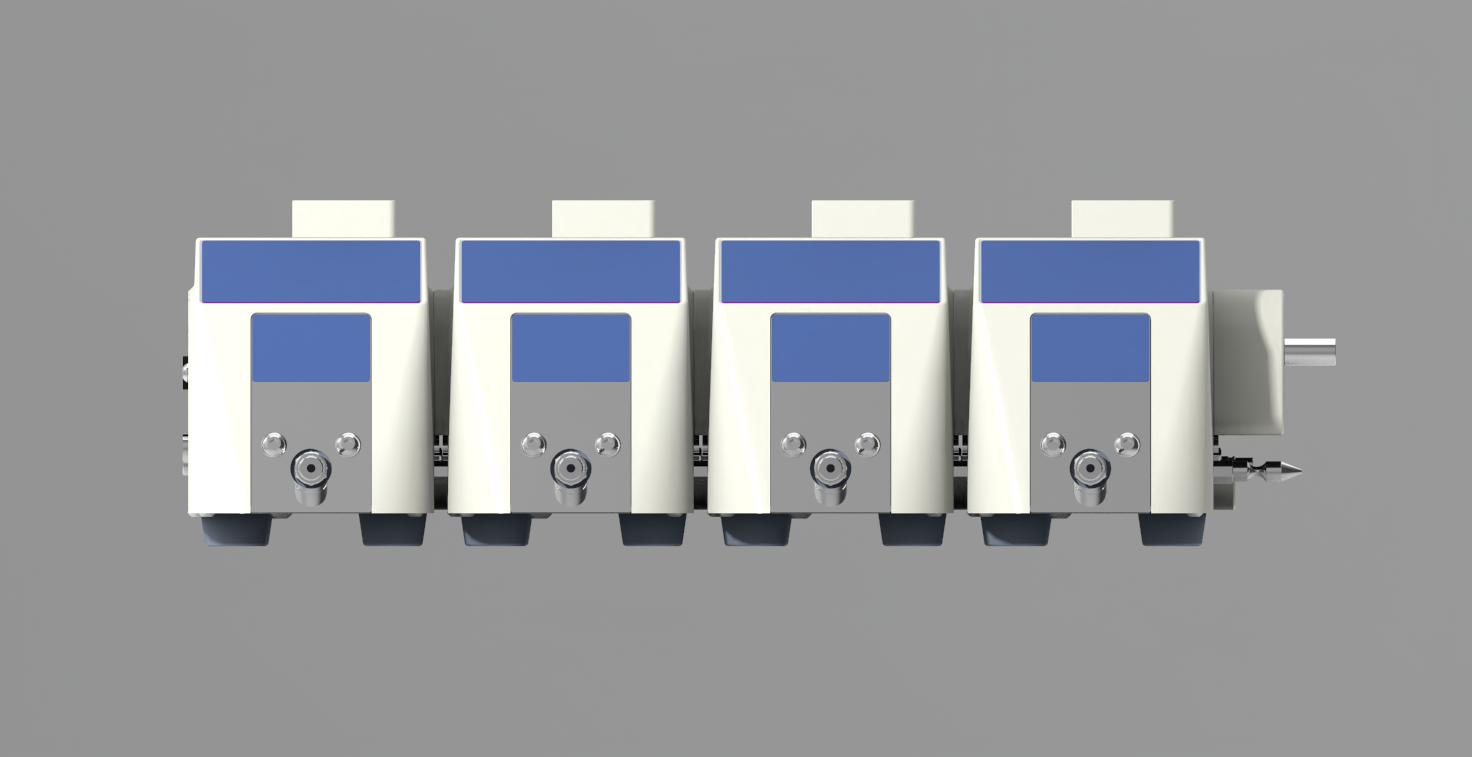

RESULT

As Blacksheep concludes the beta phase, our collaboration with the UK company has successfully produced an optimized microfluidic pressure pump design. The achievement of enhanced reliability, and improved efficiency positions the pressure pump for a seamless transition to the production phase.

Enhanced operational efficiency

The adjustment in valve count, coupled with the orifice enlargement, enhances operational theory. This streamlined design not only preserves the pump’s functionality and improvements but also simplifies assembly and maintenance processes.

Reduced wiring complexity

The redesigned microfluidic pressure pump has impressively reduced the number of wires from 16 to just 3. Integration of connections within the pump has eliminated the need for external wires, minimizing the risk of short circuits and losses during product transportation.

Streamlined design

A new cover has been designed to fulfill the moldability criterion without requiring painting, while also being noticeably thinner than its predecessor.

Cost-effectiveness measures

In pursuit of cost-effectiveness, a reduction in the number of valves has been implemented, decreasing from 4 to 3. This step aligns with the goal of economizing production without compromising the pump’s functionality.

Challenges

Unclear technical documentation

Improving the new pump to address issues in the old version was daunting due to unclear technical requirements. The old version had been in use for over a decade with lost or unavailable documentation. To navigate this challenge, we embarked on a comprehensive reverse engineering process and engaged experienced engineers to decipher the old version’s functionality, allowing us to develop a clearer path forward.

Engineering integration challenge

We faced two key challenges: unfamiliar orifice processing, requiring innovative approaches and external expertise due to a 0.1mm ultrafine diameter, and conductor minimization, which we addressed with inventive component connection using wireless tech and integrated circuits to reduce conductors inside the pump.

Supplier challenges

We encountered significant challenges with the supplier due to our stringent requirements, which exceeded their capabilities. This led to prolonged discussions and the need to find solutions. Our strategy was clear – maintain transparent communication with our suppliers. We collaboratively worked towards solutions, and explored the possibility of supplier development when necessary to ensure our project’s success.

Get started today

To find out how to partner with Blacksheep, send us your information.